Accurate positioning, multi groove forming, stable, fast and efficient;

Morse taper shank: 4 # / 5 #, 3 #, or 6 # [any shape can be customized];

Speed: 63 - 200 rpm;

Power source: the drilling machine rotates clockwise;

Detailed information and operation method can be obtained by email

Email: kxbg365@qq.com

WeChat:czzhouhui

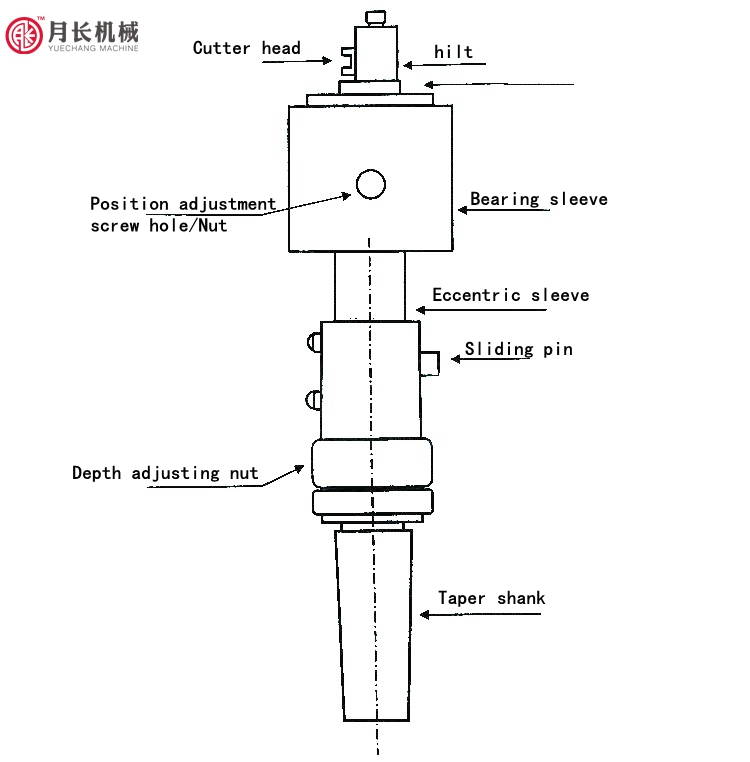

Structure chart:

It consists of three parts: 1. Main body, 2. Cutter bar, 3. Blade.

Detailed information and operation method can be obtained by email

Email: kxbg365@qq.com

WeChat:czzhouhui

Detailed information and operation method can be obtained by email

Email: kxbg365@qq.com

After slotting, the tightness and pull-out force of the connection between the tube and tube sheet are increased, and the connection strength with the tube is greatly improved, which is not easy to loosen and stretch; It can also reduce or eliminate the expansion problems and troubles caused by the gap or air hole caused by thermal expansion and cold contraction or other factors. The accuracy of slotting in tubesheet inner hole directly affects the quality of tube expansion. Yckcq-01 / 02 / 03 series high precision groover is a special tool for slotting the inner hole of heat exchanger tube sheet, which can meet the requirements of hydraulic expansion.

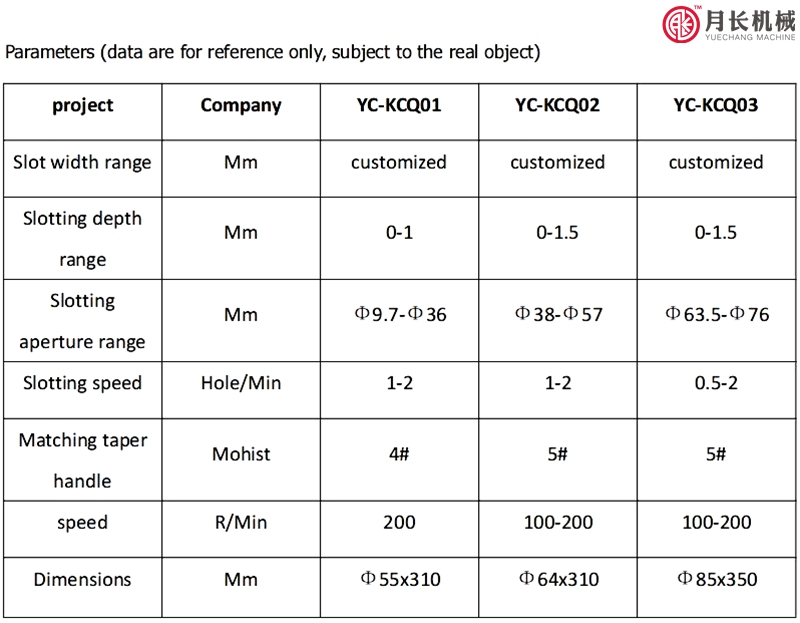

Technical parameter:

Operation method:

1. Tool selection: select the tool according to the slotting requirements of the tubesheet to be processed. At the same time, you can also provide your own tool bar according to the slotting requirements of different rules. The blade hole must be finished and formed, and the blade grinding must meet the processing requirements.

2. Knife loading:

3. Clamping: slotter can be installed on ordinary radial drilling machine or drilling center by Morse handle.

4. Main engine speed regulation: according to the requirements of different specifications of processing, select the reasonable speed from the technical parameter table.

5. Feed: when the top cone of the main body is aligned with the hole to be machined, first adopt no-load free positioning, then fix the rocker arm of the drilling machine, press down the force, drive the main body to rotate through the rotation of the main shaft, and make the cutter bar automatically feed horizontally until the required groove is finished. The operation process of each hole only takes 0.5-1 minute.

Note:

1. In the process of slotting, the rotating speed should not be too high to avoid damaging the cutting tools and parts.

2. The bolt for fixing the blade must be tightened, but not too hard!

3. When slotting, the cutter should position the workpiece freely, otherwise it will cause eccentric slotting.

4. The sliding part should keep good lubrication performance. Lubricating oil should be filled frequently and kept clean without jamming.

5. Fill bearing lubricating oil regularly.

6. The selection of tool holder and tool should be within the parameter range.